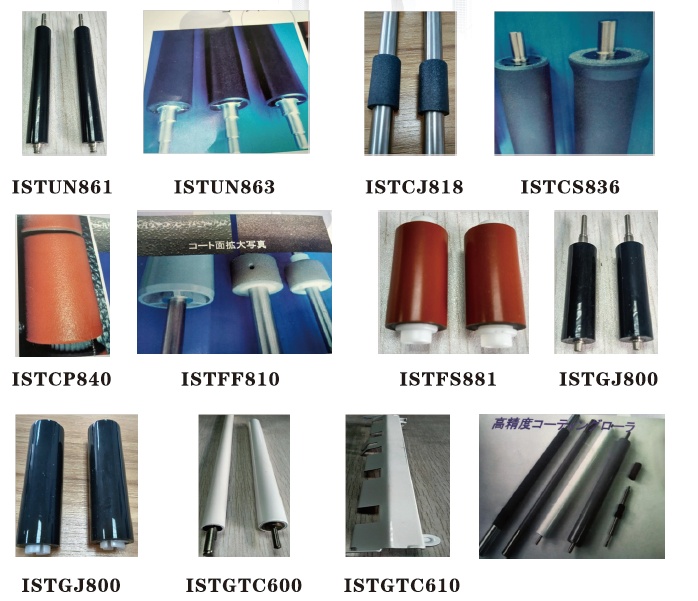

We can provide printing roller, paper roller, paper feed roller,Twist Roller, the main materials are EPDM, silicone rubber, Pu rubber, SBR.

Type:

- Industrial Rollers: Used in manufacturing processes, these rollers are designed to withstand heavy-duty applications.

- Printing Rollers: Specifically designed for the printing industry, they ensure high-quality print results.

- Conveyor Rollers: Used in conveyor systems to move products or raw materials.

- Coating Rollers: Used to apply coatings or laminates to various surfaces.

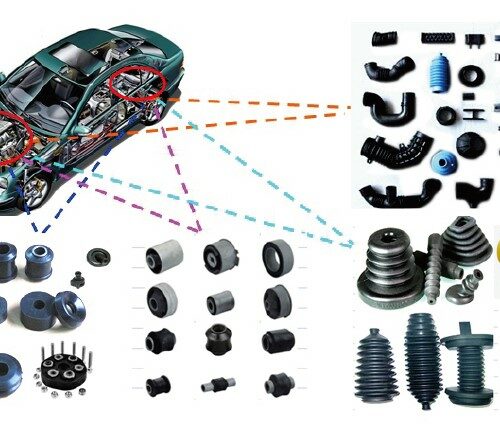

Application:

- Manufacturing: Rollers rubber is essential in various manufacturing processes, ensuring products are made with precision.

- Printing: They play a pivotal role in ensuring that ink is transferred onto paper or other materials uniformly.

- Material Handling: Used in conveyor systems in warehouses, production lines, and airports.

- Surface Treatment: In industries where surfaces of materials need to be treated, coated, or laminated.

Benefits:

- Durability: Made to last, they can withstand the wear and tear of industrial applications.

- Efficiency: Helps in speeding up processes, ensuring tasks are completed faster.

- Precision: Ensures tasks are done accurately, be it printing or material handling.

- Cost-Effective: In the long run, their durability and efficiency can lead to cost savings.

- Versatility: Can be used in a variety of industries and applications.

Feature:

- High-Quality Material: Made from the best quality rubber, ensuring longevity.

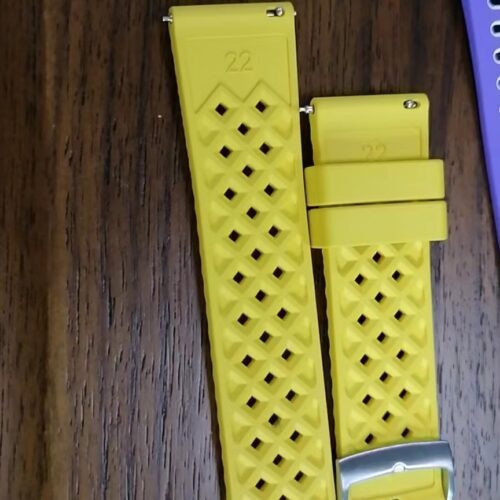

- Customizable: Can be tailored to meet specific industry needs.

- Resistant: Designed to be resistant to chemicals, heat, and other industrial elements.

- Eco-Friendly: Many rollers rubber are made from sustainable materials, making them environmentally friendly.

- Low Maintenance: Designed to require minimal maintenance, reducing downtime.

Work Process:

- Selection: The right type of rollers rubber is chosen based on the application.

- Installation: The rollers are installed in the machinery or equipment.

- Operation: The machinery is operated, with the rollers playing a crucial role in the process, be it printing, conveying, or any other application.

- Maintenance: Regular checks are done to ensure the rollers are in good condition. Any necessary maintenance or cleaning is carried out.

- Replacement: After a significant period, when wear and tear are evident, the rollers are replaced to ensure optimal performance.

In essence, rollers rubber is an indispensable component in various industries, offering a range of benefits and features that enhance operational efficiency and productivity.

FAQ about Rollers Rubber

What are rollers rubber? Rollers rubber are cylindrical components made of rubber, used in various industries for applications like printing, manufacturing, and material handling.

Why is rubber used for rollers? Rubber offers excellent flexibility, durability, and resistance to various industrial elements, making it an ideal material for rollers that need to withstand different conditions and pressures.

How long do rollers rubber typically last? The lifespan of rollers rubber varies based on the application, frequency of use, and maintenance. With proper care, they can last for several years.

Can I customize the size and shape of my rollers rubber? Yes, many manufacturers offer customization options to cater to specific industry needs and machinery requirements.

How do I maintain my rollers rubber? Regular cleaning to remove any debris and periodic inspections for wear and tear are essential. Depending on the application, specific maintenance procedures might be recommended by the manufacturer.

Are there different types of rubber used in these rollers? Yes, depending on the application, different types of rubber, such as natural rubber, neoprene, or silicone, might be used to achieve desired properties.

Is it environmentally friendly to use rollers rubber? Many rollers rubber are made from sustainable materials or can be recycled, making them environmentally friendly. However, it’s always good to check with the manufacturer about their environmental practices.

What industries commonly use rollers rubber? Rollers rubber are used in various industries, including printing, manufacturing, material handling, and surface treatment, among others.

How do I know when it’s time to replace my rollers rubber? Signs of wear and tear, decreased efficiency, or visible damage are indicators that it might be time to replace your rollers rubber.

Can rollers rubber withstand chemicals and high temperatures? Yes, many rollers rubber are designed to be resistant to chemicals and high temperatures. However, it’s essential to choose the right type of rubber material based on the specific conditions of your application.

How does the price of rollers rubber vary? The price can vary based on the type of rubber used, size, customization, and other specific features required for the application. It’s best to get a quote from manufacturers based on your needs.

FAQ for Rollers Rubber Buyer

1. What types of rubber do you use in the production of your rollers? We utilize a range of high-quality rubber materials, including natural rubber, neoprene, and silicone, tailored to specific industrial applications. Our selection ensures optimal performance and longevity for each roller’s intended use.

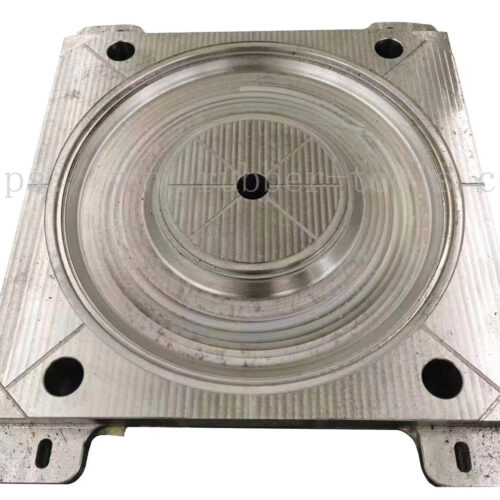

2. How do you ensure the durability and longevity of your rollers rubber? Our rollers are manufactured under stringent quality control measures, using state-of-the-art technology and machinery. Each roller undergoes rigorous testing to ensure it meets our high standards of durability and performance.

3. Can you customize rollers rubber to fit specific machinery and applications? Absolutely. We pride ourselves on our ability to work closely with clients to design and produce rollers that fit their unique specifications and requirements. Our team of engineers is always ready to collaborate and provide solutions.

4. What measures do you take to ensure the eco-friendliness of your products? Sustainability is a core value for us. We source our rubber from responsible and sustainable suppliers. Additionally, our manufacturing processes are designed to minimize waste and reduce our carbon footprint.

5. How do you handle bulk orders and tight delivery schedules? With our advanced manufacturing facilities and efficient logistics team, we are well-equipped to handle bulk orders and ensure timely delivery. We understand the critical nature of industrial timelines and are committed to meeting our clients’ needs.

6. Are there any certifications or standards that your rollers rubber comply with? Yes, our products comply with international quality and safety standards. We are also regularly audited by third-party agencies to ensure consistent quality and adherence to global best practices.

7. How do you address after-sales concerns or issues? Customer satisfaction is paramount to us. We have a dedicated after-sales team that addresses any concerns promptly. Whether it’s a product query or a maintenance issue, we’re here to assist and ensure your operations run smoothly.

8. What sets your company apart from other rollers rubber manufacturers? Our commitment to quality, innovation, and customer satisfaction sets us apart. With years of experience in the industry, we have honed our processes and products to offer the best in class solutions to our B2B clients.

In conclusion, as a reliable and professional manufacturer, we are dedicated to providing top-quality rollers rubber that meets the diverse needs of our B2B clients. Our expertise and commitment to excellence ensure that you receive products that are a cut above the rest.