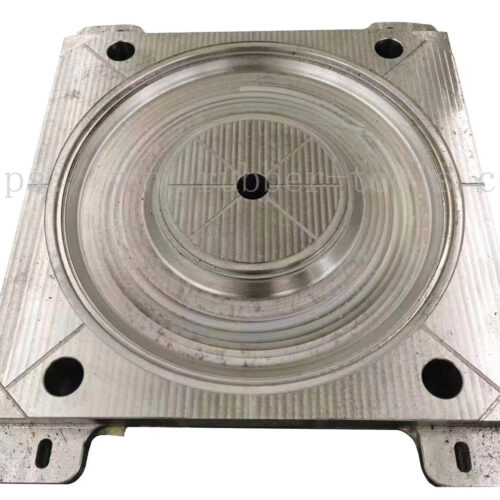

We can provide FKM rubber products processing custom.We have own mold workshop, you can design and manufacture their own mold.

FKM Rubber: A Comprehensive Overview

Type:

- Synthetic Rubber: FKM rubber, also known as Fluoroelastomer, is a high-performance synthetic rubber. It is specially formulated to meet the demands of extreme conditions and challenging applications.

Application:

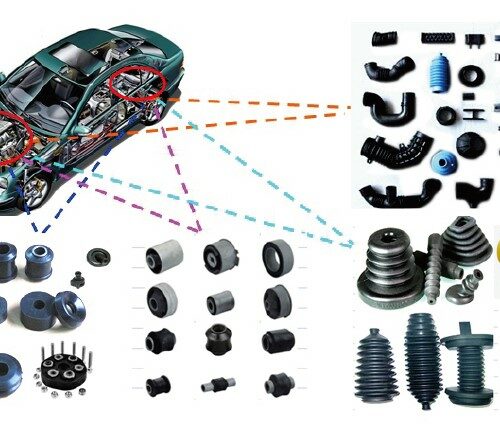

- Automotive Industry: Used in fuel system seals, hoses, and gaskets due to its resistance to petroleum-based fluids and high temperatures.

- Aerospace: Utilized in seals and gaskets that come into contact with jet fuel and other aerospace-specific chemicals.

- Oil and Gas: Ideal for seals, O-rings, and gaskets in drilling and production equipment because of its resistance to oil-based fluids.

- Chemical Processing: As seals and gaskets in equipment and machinery that handle aggressive chemicals.

- Industrial Equipment: For components that require resistance to heat, chemicals, and other aggressive media.

Benefits:

- Extended Lifespan: FKM rubber components tend to have a longer service life due to their resistance to harsh conditions, reducing replacement frequency.

- Enhanced Performance: Offers consistent performance even in extreme conditions, ensuring reliability.

- Cost Savings: While the initial investment might be higher, the long-term savings in maintenance, replacements, and reduced downtime make FKM rubber a cost-effective choice.

Features:

- Chemical Resistance: Exceptional resistance to a wide array of chemicals, including hydrocarbons, oils, and acids.

- High-Temperature Tolerance: Can withstand elevated temperatures, making it ideal for applications where heat resistance is crucial.

- Low Gas Permeability: Exhibits minimal gas permeation, making it suitable for vacuum and high-pressure applications.

- Environmental Resistance: Resistant to ozone, UV radiation, and atmospheric oxidation, ensuring durability in varying environmental conditions.

Work Process:

- Polymerization: The production of FKM rubber begins with the polymerization of multiple monomers, including vinylidene fluoride.

- Compounding: The polymer is then mixed with specific additives, fillers, and curing agents to enhance its properties. This mixture is tailored based on the desired end-use application.

- Molding and Shaping: The compounded FKM rubber is then molded into the desired shape, be it sheets, seals, or any other component.

- Curing: Post molding, the rubber undergoes a curing or vulcanization process, where it’s exposed to high temperatures. This step solidifies the rubber and sets its final properties.

- Quality Control: Every batch of FKM rubber and its components undergo rigorous testing to ensure they meet the set standards and specifications.

FAQ about FKM Rubber

What is FKM rubber and how does it differ from other types of rubber? FKM rubber, also known as Fluoroelastomer, is a high-performance synthetic rubber. It’s specifically designed to resist a wide range of chemicals and high temperatures, making it distinct from other standard rubbers.

Why is FKM rubber more expensive than other rubbers? The production of FKM rubber involves complex polymerization processes and uses high-quality monomers. Its superior resistance to chemicals, heat, and environmental factors also contribute to its premium pricing.

Can FKM rubber be used in food processing applications? While FKM rubber exhibits excellent chemical resistance, it’s essential to ensure that the specific grade of FKM rubber used is compliant with food safety standards before using it in food processing applications.

How does FKM rubber perform in extremely cold environments? While FKM rubber is renowned for its high-temperature resistance, its flexibility and performance can be compromised in extremely cold conditions. It’s crucial to select the right grade of FKM rubber designed for low-temperature applications if required.

Is FKM rubber resistant to UV and ozone? Yes, FKM rubber offers excellent resistance to UV radiation and ozone, making it suitable for outdoor applications where other rubbers might degrade.

How long does FKM rubber last in real-world applications? The lifespan of FKM rubber components varies based on the specific application and environmental conditions. However, due to its inherent durability and resistance properties, FKM rubber typically has a longer service life compared to other rubbers.

Can FKM rubber be recycled? While FKM rubber can be recycled, the process is more complex than recycling natural rubber. It’s essential to work with specialized recycling facilities that can handle FKM rubber.

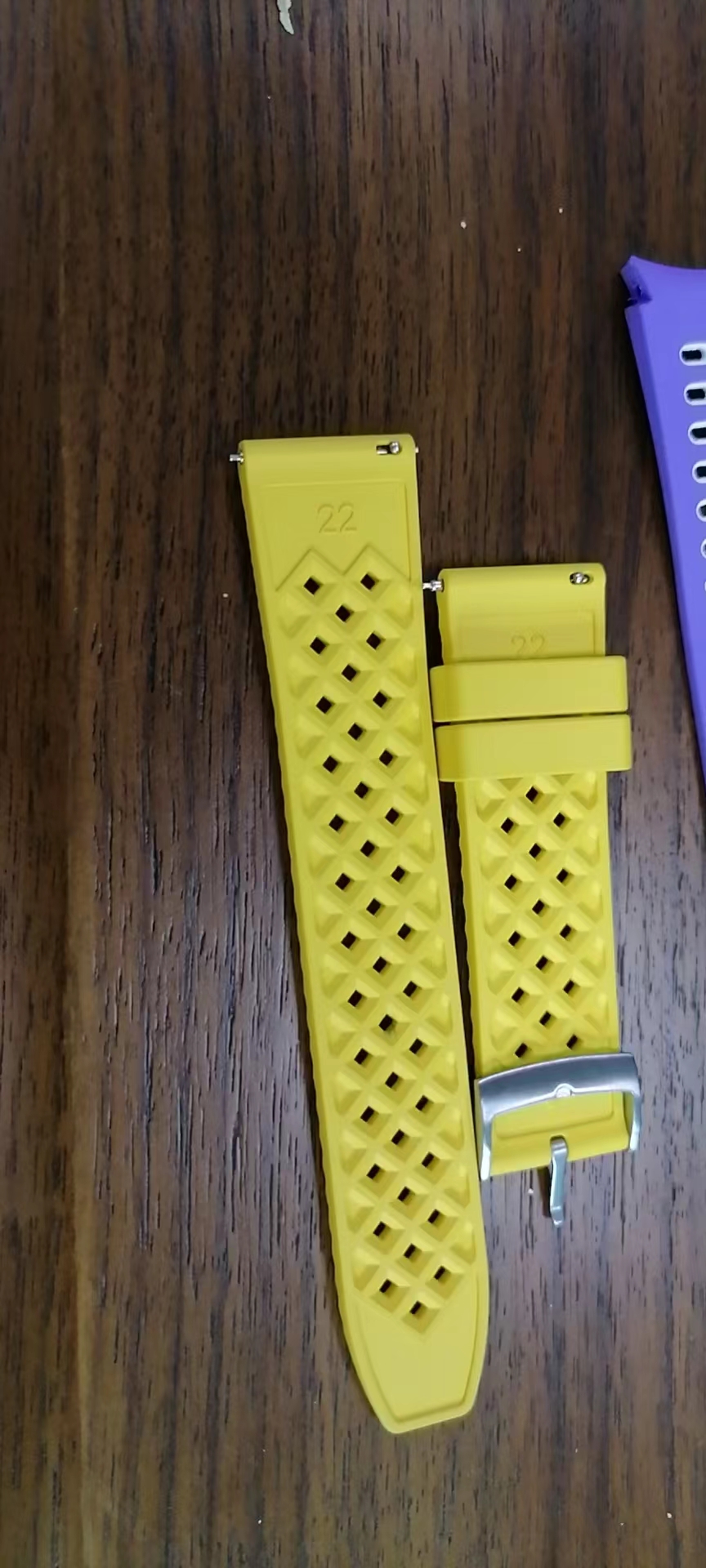

What colors are available for FKM rubber products? While the natural color of FKM rubber is brown, it can be compounded with various colorants to achieve a range of colors based on customer requirements.

How do I store FKM rubber products to ensure longevity? It’s best to store FKM rubber products in a cool, dry place away from direct sunlight and extreme temperatures. Proper storage ensures the rubber retains its properties and extends its service life.

Are there any chemicals or environments where FKM rubber should not be used? While FKM rubber is resistant to many chemicals, it’s not suitable for all. It’s essential to consult with the manufacturer or technical datasheets to determine its compatibility with specific chemicals or environments.

FAQ for FKM Rubber Buyer

What sets your FKM rubber apart from other suppliers in the market? Our FKM rubber is produced using advanced polymerization techniques and high-quality monomers. We prioritize consistency, ensuring that every batch meets stringent quality standards, making us a trusted supplier in the industry.

Can you provide custom formulations of FKM rubber based on our specific requirements? Absolutely. We understand that every business has unique needs. Our technical team collaborates closely with clients to develop custom formulations tailored to specific applications, ensuring optimal performance.

How do you ensure the consistent quality of your FKM rubber across large orders? We have a robust quality control system in place. Every batch of our FKM rubber undergoes rigorous testing in our state-of-the-art labs. Our commitment to quality ensures that you receive a consistent product, order after order.

What is the lead time for bulk orders of FKM rubber? While lead times can vary based on order size and any custom requirements, we have optimized our production processes to ensure timely delivery. We’ll provide a detailed timeline once we understand your specific needs.

Do you offer any warranties or guarantees on your FKM rubber? Yes, we stand by the quality of our products. Our FKM rubber comes with a comprehensive warranty that covers manufacturing defects and performance inconsistencies, underscoring our commitment to excellence.

How do you handle international shipping and logistics? We have established partnerships with leading logistics providers to ensure smooth international shipping. Our logistics team oversees the entire process, from packaging to delivery, ensuring your order reaches you in perfect condition.

Are there any volume discounts or special pricing structures for long-term contracts? We value our B2B partnerships and offer competitive pricing models. Volume discounts and special pricing structures are available for large orders and long-term contracts, reflecting our commitment to fostering lasting business relationships.

How do you address concerns or issues post-purchase? Customer satisfaction is paramount to us. We have a dedicated after-sales support team ready to address any concerns or issues. Whether it’s a product query or technical assistance, we’re here to help.

Can we visit your production facility to understand the manufacturing process better? Certainly. We believe in transparency and welcome our B2B partners to visit our production facility. It’s an opportunity to witness our advanced manufacturing processes and commitment to quality firsthand.

How do you ensure the ethical and sustainable production of FKM rubber? We adhere to all local and international regulations concerning ethical and sustainable production. Our operations prioritize environmental responsibility, and we continuously seek ways to reduce our carbon footprint, making us a responsible choice for your business needs.