We have 3 plastic production suppliers, customers can inquiry, quality control, delivery supervision services.

Custom Plastic Parts: A Comprehensive Overview

Type:

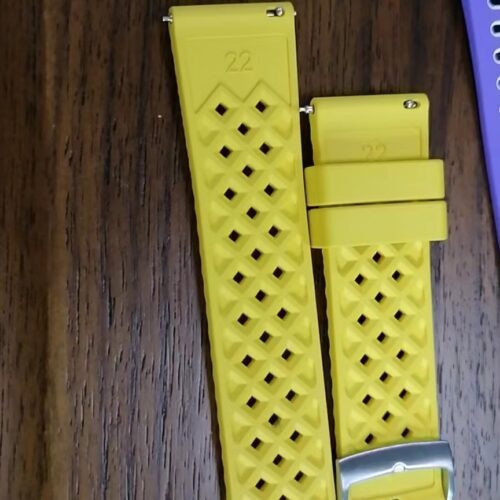

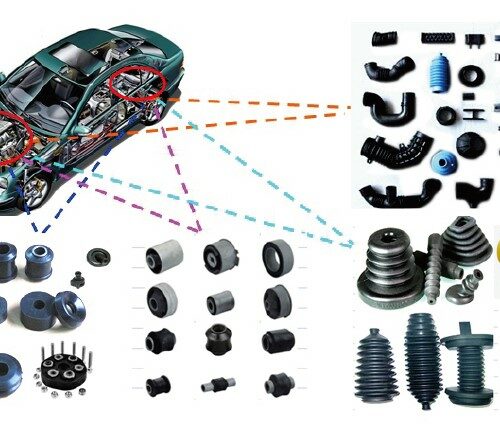

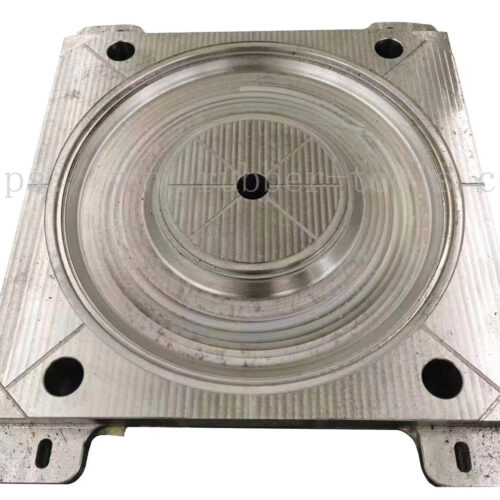

- Injection Molded Parts: Utilizing molten plastic injected into molds to create complex shapes and designs.

- Thermoformed Parts: Plastic sheets are heated and formed over a mold, typically used for larger parts.

- Extruded Parts: Continuous shapes (like tubes or profiles) produced by forcing melted plastic through a die.

- Rotational Molded Parts: Hollow parts created by heating plastic inside a rotating mold.

Application:

- Automotive: Custom Plastic Parts are used for interior components, bumpers, and more.

- Medical: Precision parts for medical devices, equipment, and disposables.

- Electronics: Enclosures, connectors, and other components for electronic devices.

- Consumer Goods: Everything from toys to household items, made to specific designs and needs.

- Aerospace: Lightweight, durable components for aircraft and space applications.

Benefits:

- Versatility: The ability to create parts of any shape, size, and design.

- Cost-Effective: Custom plastic manufacturing can be more economical than other materials, especially at scale.

- Lightweight: Plastic parts are typically lighter than metal counterparts, reducing overall product weight.

- Durability: Modern plastics offer long-lasting durability, resisting wear, tear, and environmental factors.

- Rapid Prototyping: Quick turnaround from design to prototype, speeding up the development process.

Feature:

- High-Precision: Advanced manufacturing techniques ensure parts are produced to exact specifications.

- Material Variety: A wide range of plastics, from flexible to rigid, transparent to opaque, to suit different needs.

- Eco-Friendly Options: Many plastics are recyclable, and processes can be optimized for minimal waste.

- Integrated Additives: Options to integrate UV stabilizers, flame retardants, or colorants directly into the plastic.

- Consistent Quality: Automated processes and quality checks ensure consistent production quality.

Work Process:

- Consultation: Engage with the client to understand specific needs, designs, and application requirements.

- Design & Prototyping: Using CAD tools, the design is finalized, and prototypes are created for validation.

- Material Selection: Based on the application, the best-suited plastic material is chosen.

- Manufacturing: Utilizing the appropriate technique (injection molding, thermoforming, etc.), the Custom Plastic Parts are produced.

- Quality Control: Each part undergoes rigorous quality checks to ensure it meets the set standards.

- Packaging & Delivery: Parts are packaged securely and delivered to the client or moved to the next phase of assembly.

- After-Sales Support: Continuous support is provided for any queries, modifications, or further requirements.

In essence, Custom Plastic Parts offer a versatile and efficient solution for a myriad of industries and applications. With a focus on precision, quality, and client satisfaction, they stand as a testament to modern manufacturing excellence.

FAQ about Custom Plastic Parts

What are Custom Plastic Parts? Custom Plastic Parts are components specifically designed and manufactured to meet unique specifications and requirements, using various plastic materials and manufacturing techniques.

How do you ensure the precision of the parts? We utilize advanced CAD tools and state-of-the-art manufacturing processes, coupled with rigorous quality control checks, to ensure each part meets the exact specifications provided by the client.

Can I choose the type of plastic material used? Absolutely. We offer a wide range of plastic materials to choose from, and our experts can also provide recommendations based on the intended application and performance requirements.

What is the lead time for producing Custom Plastic Parts? The lead time varies based on the complexity of the design, the chosen manufacturing process, and order volume. However, we always strive to deliver in the shortest possible time without compromising on quality.

Are there any minimum order quantities? While we can accommodate orders of all sizes, there might be certain cost advantages to producing larger quantities due to economies of scale.

How do you ensure the durability and longevity of the parts? We use high-quality plastic materials known for their durability. Additionally, our manufacturing processes are optimized to produce parts that can withstand the intended use and environmental conditions.

Is it possible to produce eco-friendly or biodegradable Custom Plastic Parts? Yes, we offer options for eco-friendly and biodegradable plastics. Our team can guide you on the best choices based on your sustainability goals.

Do you offer post-production assembly or finishing services? Yes, we provide a range of post-production services, including assembly, finishing, and packaging, to deliver a complete solution to our clients.

How do you handle design modifications or changes during the production process? We maintain open communication with our clients throughout the production process. If design modifications are needed, we assess the feasibility and potential impact on lead time and cost before implementing changes.

What sets your company apart in the Custom Plastic Parts industry? Our commitment to quality, precision, and customer satisfaction, combined with our expertise and advanced manufacturing capabilities, positions us as a leading provider in the Custom Plastic Parts industry.

In conclusion, we are dedicated to providing top-quality Custom Plastic Parts tailored to meet the specific needs of our clients. Our expertise and advanced capabilities ensure that you receive parts that are a perfect fit for your requirements.

FAQ for Custom Plastic Parts Buyer

What manufacturing techniques do you employ for producing Custom Plastic Parts? We utilize a range of advanced manufacturing techniques, including injection molding, thermoforming, extrusion, and rotational molding, ensuring we can cater to diverse design complexities and volume requirements.

How do you guarantee the precision and quality of the Custom Plastic Parts? Our production process integrates state-of-the-art CAD tools and precision machinery. Every part undergoes stringent quality control checks, from raw material selection to final inspection, ensuring consistency and adherence to client specifications.

Can you handle bulk orders and tight production schedules? Certainly. Our advanced manufacturing facilities are designed for scalability, allowing us to efficiently manage large orders. Our dedicated logistics and production teams work in tandem to ensure timely delivery, even on tight schedules.

Are there sustainable or eco-friendly plastic options available? Yes, sustainability is integral to our operations. We offer a range of eco-friendly and biodegradable plastic options, ensuring our clients can meet their environmental commitments without compromising on quality.

Do you offer design consultation and prototyping services? Absolutely. Our team of experienced engineers collaborates closely with clients, offering design consultations to optimize part functionality and manufacturability. We also provide rapid prototyping services to validate designs before full-scale production.

How do you address post-production modifications or concerns? Client satisfaction is paramount. If there are any post-production concerns or modifications needed, our team engages proactively to address them, ensuring the final product aligns perfectly with client expectations.

What certifications or standards do your Custom Plastic Parts adhere to? Our products comply with international quality and safety standards. We maintain regular audits and certifications to validate our commitment to excellence and industry best practices.

How competitive are your pricing models for Custom Plastic Parts? While we prioritize quality and precision, our optimized manufacturing processes and economies of scale allow us to offer competitive pricing, ensuring our clients receive exceptional value.

Do you provide after-sales support and services? Yes, our relationship with clients extends beyond the sale. We offer comprehensive after-sales support, addressing any queries, maintenance needs, or further requirements to ensure seamless integration and operation of our Custom Plastic Parts.

Why should businesses choose your company for Custom Plastic Parts? Our legacy in the industry is built on precision, quality, and unwavering commitment to client success. With our advanced capabilities, expert team, and client-centric approach, we stand as a trusted partner for all Custom Plastic Parts needs.

In essence, as a leading manufacturer in the Custom Plastic Parts domain, we are dedicated to delivering excellence at every step, ensuring our B2B clients receive parts that are a testament to quality and precision.