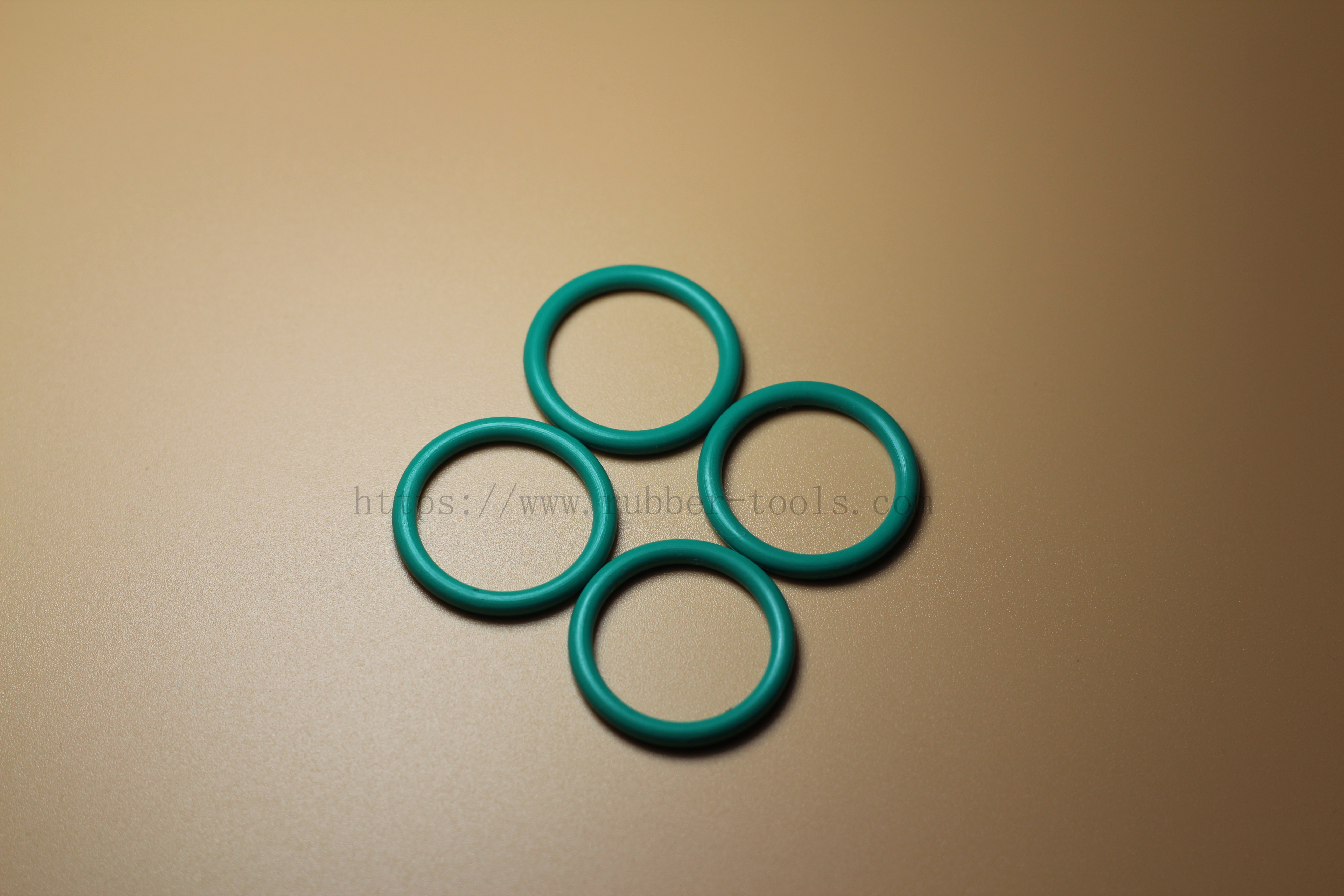

O-ring is applicable to be installed on various mechanical equipment, and plays a sealing role in static or moving state at specified temperature, pressure, and different liquid and gas media. Various types of sealing elements are widely used in machine tools, ships, automobiles, aerospace equipment, metallurgical machinery, chemical machinery, engineering machinery, construction machinery, mining machinery, petroleum machinery, plastic machinery, agricultural machinery, and various instruments and meters.

O-ring is mainly used for static seal and reciprocating seal. When used for rotary motion seal, it is limited to low-speed rotary seal device. The O-ring is generally installed in the groove with rectangular section on the outer circle or inner circle for sealing. The O-ring still plays a good sealing and shock absorption role in the environment of oil resistance, acid and alkali resistance, grinding, chemical corrosion, etc. Therefore, O-ring is the most widely used seal in hydraulic and pneumatic transmission systems.

Types of O-rings:

- Nitrile (Buna-N): Suitable for most applications, especially those involving oils and petroleum derivatives.

- Silicone: Ideal for high and low-temperature applications, often used in food and medical industries.

- Fluorocarbon (Viton): Resistant to chemicals and offers excellent high-temperature performance.

- Neoprene: Good for refrigeration systems due to its excellent resistance to ammonia and Freon.

- EPDM: Best for brake systems due to its resistance to brake fluids, water, and steam.

Applications of O-rings:

- Hydraulic Systems: Prevents fluid leakage between connected parts.

- Pneumatic Systems: Seals air and prevents loss of pressure.

- Water Filtration Systems: Ensures no contaminants bypass the filter.

- Automotive Engines: Used in fuel injectors, pumps, and other components to prevent fluid or air leaks.

- Aerospace: Critical in sealing connections in aircraft engines and systems.

Benefits of O-rings:

- Cost-Effective: Provides an efficient sealing solution without a significant investment.

- Versatile: Suitable for a wide range of applications across various industries.

- Durable: Designed to last, reducing the need for frequent replacements.

- Easy Installation: Simple design ensures quick and hassle-free installation.

- Space-Efficient: Compact design ensures it doesn’t occupy much space, making it ideal for intricate machinery.

Features of O-rings:

- Elasticity: Allows the O-ring to return to its original shape after being compressed, ensuring a consistent seal.

- Chemical Resistance: Certain O-ring materials can resist a wide range of chemicals, making them suitable for various applications.

- Temperature Resistance: Can operate efficiently over a broad temperature range, from very cold to very hot environments.

- Pressure Resistance: Designed to withstand varying pressure levels, ensuring a tight seal in both low and high-pressure systems.

- Dimensional Stability: Maintains its size and shape under stress, ensuring a consistent and reliable seal.

O-rings, with their simple yet effective design, have become an indispensable component in various industries. Their ability to provide a reliable seal in diverse conditions makes them a preferred choice for many applications.

Frequently asked questions about O-rings:

1. What are O-rings made of? Answer: O-rings can be made from a variety of materials, including Nitrile (Buna-N), Silicone, Fluorocarbon (Viton), Neoprene, EPDM, and more. The choice of material depends on the specific application and the conditions the O-ring will be exposed to.

2. How do I choose the right O-ring material for my application? Answer: The choice of O-ring material depends on the operating environment, including the type of fluids it will be in contact with, temperature range, pressure levels, and other specific conditions. It’s essential to consult with an O-ring specialist or refer to material compatibility charts to make an informed decision.

3. Why do O-rings fail? Answer: O-rings can fail for various reasons, including incorrect size or installation, material incompatibility with the operating environment, exposure to extreme temperatures or pressures, and wear and tear over time.

4. Can O-rings be reused after removal? Answer: While it might be tempting to reuse an O-ring, it’s generally not recommended. Once an O-ring has been compressed, it may not provide the same level of sealing efficiency when reused. For critical applications, always use a new O-ring to ensure optimal performance.

5. How should I store unused O-rings? Answer: O-rings should be stored in a cool, dry place away from direct sunlight. It’s also essential to keep them away from ozone sources, as ozone can degrade certain O-ring materials. Store them flat and avoid stretching or bending them.

6. What’s the difference between static and dynamic O-ring applications? Answer: In static applications, the O-ring remains stationary and seals a non-moving connection. In dynamic applications, there’s relative motion between parts, and the O-ring may need to seal moving components, such as in a piston or rotating shaft.

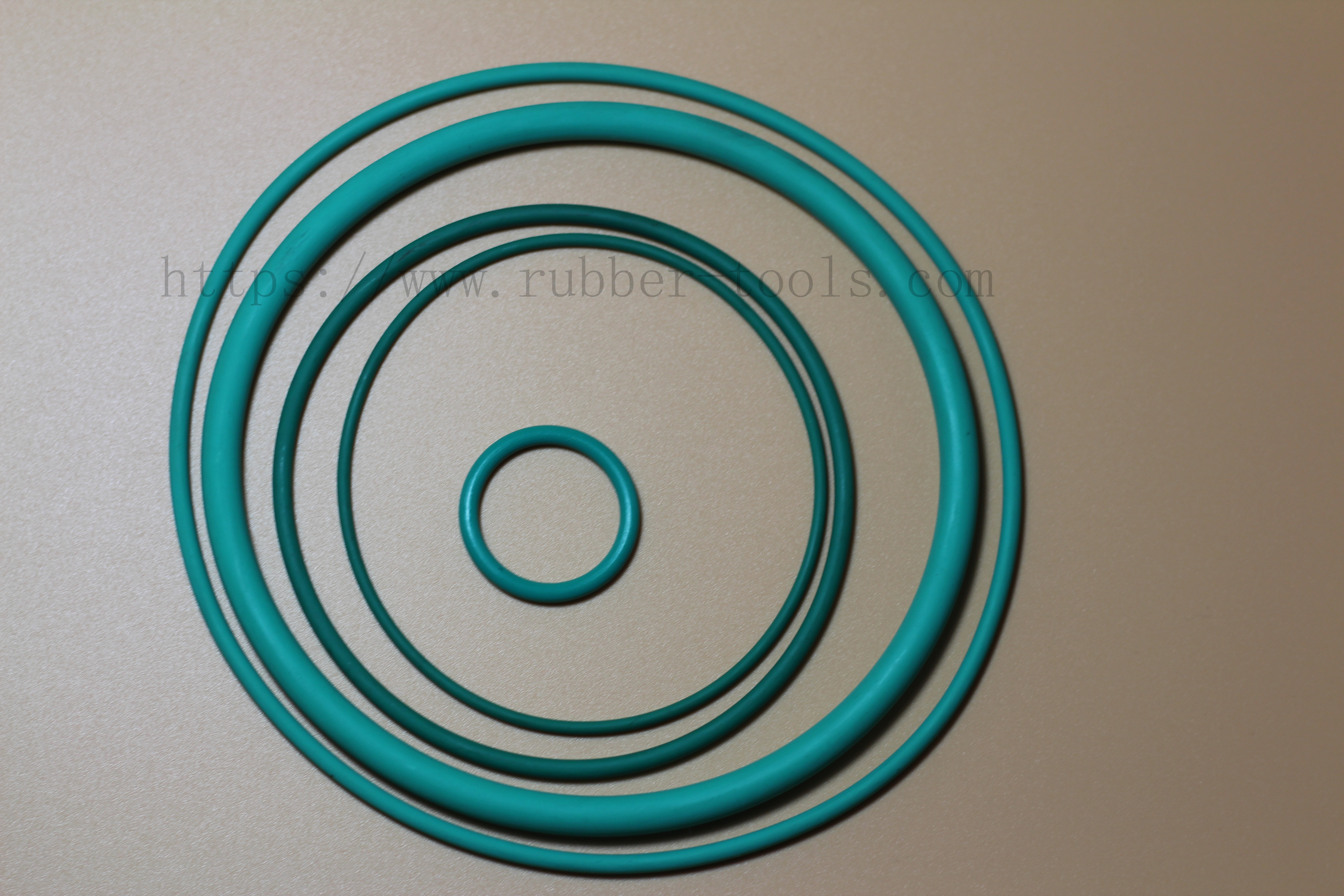

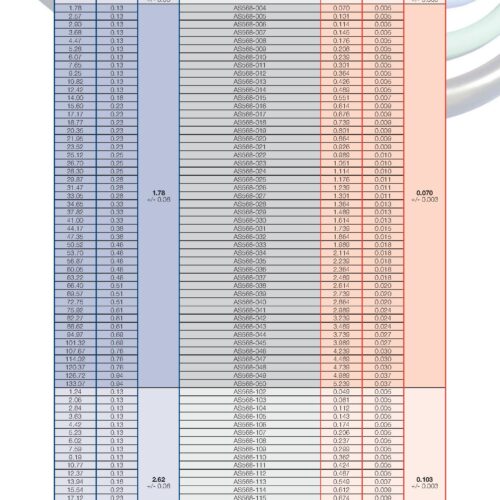

7. How do I measure an O-ring? Answer: O-rings are typically measured by their inner diameter (ID), cross-sectional diameter (thickness), and sometimes the outer diameter (OD). Accurate measurements ensure the O-ring fits correctly and provides an effective seal.

8. Can O-rings be custom-made for specific applications? Answer: Yes, many manufacturers offer custom O-ring solutions tailored to unique applications or specific requirements. This can include custom sizes, shapes, and materials.

These FAQs provide a basic understanding of O-rings, but always consult with an O-ring specialist or manufacturer for specific queries or detailed information.

FAQs for O-rings Buyer

1. What sets your O-rings apart from competitors? Answer: Our O-rings are manufactured under stringent quality control measures, using state-of-the-art technology and premium materials. This ensures superior sealing performance, longevity, and consistent quality across all batches, setting us apart in the market.

2. Can you provide O-rings tailored to specific industry standards or specifications? Answer: Absolutely. We have the capability and expertise to produce O-rings that meet specific industry standards or custom specifications. Our team collaborates closely with clients to understand their unique requirements and deliver products that exceed expectations.

3. How do you ensure the durability and longevity of your O-rings? Answer: Our O-rings undergo rigorous testing for wear resistance, chemical compatibility, and temperature endurance. By using top-tier materials and advanced manufacturing processes, we ensure that our O-rings offer extended service life even in challenging environments.

4. What materials are available for your O-rings, and how do I choose the right one? Answer: We offer O-rings in a variety of materials, including Nitrile, Silicone, Viton, and more. Our expert team can guide you in selecting the ideal material based on your application’s specific conditions, such as temperature, pressure, and chemical exposure.

5. Do you offer bulk discounts or special pricing for large orders? Answer: Yes, we value our B2B partnerships and offer competitive pricing structures for bulk orders. Please reach out to our sales team to discuss specific quantities and potential discounts.

6. How do you handle quality control and assurance for your O-rings? Answer: Quality is paramount to us. We have an in-house quality assurance team that conducts regular inspections at every production stage. Additionally, we utilize advanced testing equipment to ensure each O-ring meets our stringent quality standards before shipment.

7. What is the typical lead time for standard and custom O-ring orders? Answer: For standard O-rings, the lead time is typically 2-3 weeks. For custom orders, depending on the complexity and specifications, it may vary. However, we always strive to meet our clients’ timelines and provide expedited services when needed.

We pride ourselves on being a reliable and professional O-ring manufacturer, always prioritizing our clients’ needs and ensuring the highest quality products.